What is an Autoclave Machine?

|

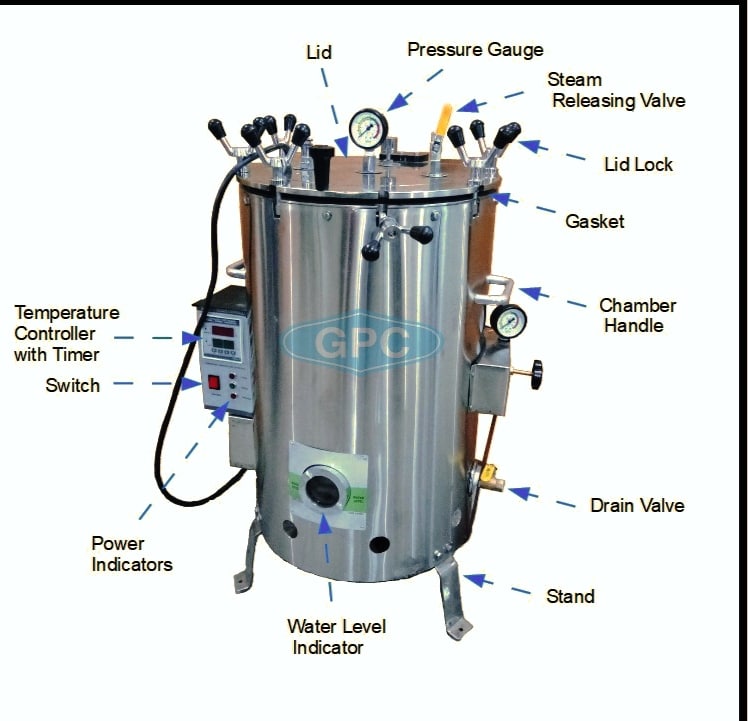

| Major parts of Autoclave Machine |

An autoclave machine is a device that uses steam and pressure to sterilize various types of equipment and materials. It is commonly used in medical facilities, laboratories, and industrial settings to kill bacteria, viruses, fungi, and other microorganisms that may be present on surfaces or in fluids.

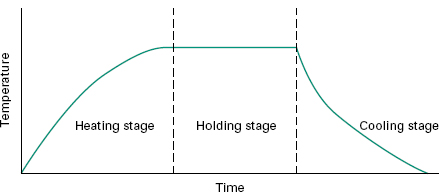

Autoclaves work by generating steam under high pressure, which is then used to kill microorganisms by exposing them to high temperatures and pressure. The machine typically consists of a chamber in which the items to be sterilized are placed, along with a heating element and a pressure valve. Once the chamber is sealed and the appropriate temperature and pressure are reached, the steam is released into the chamber to sterilize the contents.

Autoclaves are widely used in healthcare settings to sterilize surgical instruments, medical supplies, and other equipment. They are also used in research labs to sterilize biological materials, and in the food industry to sterilize food products and packaging materials.

|

| Sterilization process summery |

How are the different types of autoclave machines categorized?

There are many different aspects that can be used as a basis for the categorization of the different types of autoclaves, and some of these aspects may overlap with each other. In most cases, steam sterilizers can be differentiated by:

- function

- class

- size (capacity)

1.) Different types of autoclaves categorized by function

All

autoclaves use high-temperature and high-pressure steam to sterilize

medical equipment and waste. Their function indicates how they should be

loaded, and how they force in the steam in their chamber to sterilize

the instruments inside.

Vertical autoclaves

These types of autoclaves are loaded by opening their top lid. Especially suited for laboratory use or in smaller clinics with cramped spaces. As such, they also have a smaller capacity chamber.

Horizontal autoclaves

Front-loading steam sterilizers with a larger capacity chamber. When available space is not an issue, and you need to treat many loads a day, this one is exceptional for reducing the strain on medical staff.

Gravity displacement autoclaves

One of the most common type of autoclave that relies on using dense steam to force out the air from the machine’s chamber. They are suitable for the treatment of basic loads like flat surgical tools and certain types of biohazardous waste but are not as versatile as prevacuum autoclaves.

Pre-vacuum (prevac) autoclaves

This type of autoclave uses a vacuum pump to remove all the air from the autoclave’s chamber, allowing for better steam penetration, and the sterilization of more materials and complex loads such as medical textile products, porous loads, larger pieces of equipment, and even objects made from high-density polyethylene like the syringes of sharps and pipette tips.

2.) Different types of autoclaves categorized by class

- class N autoclave

- class B autoclave

- class sautoclave

Class B autoclave machine - Although Class B autoclave machines are small, their performance is comparable to that of the largest hospital autoclaves. Because they are smalldevices with enormous performance, theletter "B" stands for "big small sterilizers." In a Class B autoclave (class b sterilizer),any sonof load can be sterilized. Porous materials,pouched objects ,fabrics,and hollowitems like wands,turbines, and tips are allexamples. class b autoclave machine which is specialized in small steam sterilizers is the appropriate standard for this type of equipment (i.e.,machines with a sterilization chamber that is smaller than the sterilization unit).

3.) Different types of autoclaves categorized by size (capacity)

Here is a categorization that is pretty straightforward, but it certainly does not make it less important to consider. Autoclave size is also a key factor that needs to be taken into account: the right choice here depends on the amount of waste your facility needs to be treated each day, as well as the amount of available space you have.

Large steam sterilizers

The capacity of these types of autoclaves usually ranges between 110 to 880 liters. Ideal for large medical facilities like hospitals that generate a notable amount of waste each day and needs to use a lot of medical tools and equipment to treat patients.

Medium-sized steam sterilizers

The capacity of these types of autoclaves usually ranges between 75 to 200 liters. An excellent choice for dental and other clinics, biotechnological applications, or for operating theaters in hospitals.

Small (benchtop) steam sterilizers

The capacity of these types of autoclaves usually moves around 25 liters. These compact steam sterilizers are perfectly suited for smaller facilities with limited available space, and who do not need to sterilize as many medical tools each day.

How to check sterilization is success or not?

To confirm that an autoclave has successfully sterilized the items placed inside, various methods can be used to verify the effectiveness of the process. Some of these methods include:

Biological indicators: These are small strips or vials containing spores of heat-resistant bacteria that are known to be difficult to kill. These indicators are placed inside the autoclave alongside the items to be sterilized. After the sterilization cycle is complete, the indicators are removed and incubated for a specific amount of time. If no bacterial growth is detected, this confirms that the autoclave has effectively sterilized the contents.

Chemical indicators: These are labels or tapes that change color when exposed to certain conditions, such as high temperature or steam. These indicators are placed on the items to be sterilized, and if the appropriate color change occurs after the sterilization cycle is complete, this confirms that the autoclave has effectively sterilized the contents.

Chemical Indicator Physical indicators: These are instruments that measure various parameters of the sterilization process, such as temperature and pressure. These indicators can be used to ensure that the autoclave is operating correctly and that the appropriate conditions have been reached during the sterilization cycle.

It is important to follow the manufacturer's instructions for the autoclave and the sterilization process, and to regularly test and maintain the equipment to ensure that it is functioning properly.