Infusion and syringe pumps

Infusion and syringe pumps are medical devices used to administer medication and fluids to patients in a controlled and precise manner. They are commonly used in hospitals, clinics, and other medical settings where patients require intravenous (IV) therapy.

An infusion pump is a medical device that delivers fluids, such as medications, blood, and nutrients, to a patient's bloodstream in a controlled and precise manner. The pump is typically used to deliver fluids continuously or intermittently over a period of time. The device can be programmed to deliver a specific amount of fluid at a specific rate, and it can also be set to deliver a bolus, or a large volume of fluid all at once.

A syringe pump, on the other hand, is a medical device that delivers medication from a syringe into a patient's bloodstream. The device is typically used when small amounts of medication need to be delivered in a precise and controlled manner. The syringe pump can be programmed to deliver a specific amount of medication at a specific rate, and it can also be set to deliver a bolus of medication.

Both infusion and syringe pumps are important tools for medical professionals in delivering medication and fluids to patients safely and effectively. They help to minimize the risk of human error and ensure that patients receive the correct dose of medication at the right time.

How Are Infusion Pumps and Syringe Pumps Different?

Infusion pumps and syringe pumps are both used to administer medication and fluids to patients, but they differ in a few key ways.

Delivery method: Infusion pumps deliver fluids from a bag or bottle to the patient's bloodstream through an IV catheter, while syringe pumps deliver medication from a syringe to the patient's bloodstream through an IV catheter.

Volume and flow rate: Infusion pumps can deliver larger volumes of fluids, typically up to several liters, over a longer period of time, while syringe pumps are designed to deliver smaller volumes of medication, typically up to 60 milliliters, over a shorter period of time. The flow rate of infusion pumps is generally slower than that of syringe pumps.

Applications: Infusion pumps are typically used for long-term or continuous fluid and medication delivery, such as in the case of chemotherapy, total parenteral nutrition (TPN), or pain management. Syringe pumps are commonly used for short-term or intermittent medication delivery, such as in the case of anesthesia or emergency situations.

Cost: Infusion pumps are generally more expensive than syringe pumps due to their more complex mechanisms and larger size.

Overall, both infusion pumps and syringe pumps play important roles in patient care, and the choice of which device to use depends on the specific medical needs of the patient and the type of medication or fluid being administered.

How do Syringe Pumps Work?

Syringe pumps are devices that use electromechanical principles to convert rotational motion into linear motion to drive the plunger of a syringe and deliver precise amounts of solution. Understanding the design and operation of syringe pumps is crucial to selecting appropriate specifications and achieving accurate results in an experimental setup.

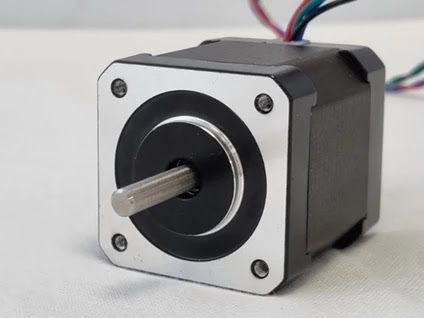

Syringe pumps use a stepper motor to deliver rotational motion, which is precisely controlled by driver electronics. Microcontrollers and advanced driver technology enable the lead screw to rotate in extremely small discrete steps, resulting in minute linear motion of the plunger and precise dispensation of small volumes of solution.

The mechanics of syringe pumps are designed to minimize frictional losses and backlash, ensuring that all rotational motion is converted to linear motion and that the torque generated by the motor is used to displace fluids rather than overcome frictional forces within the pump.

While modern syringe pumps are capable of moving very small distances, the pressure required to move viscous materials or high flow rates often necessitates a large force. If the torque generated is not high enough, the motor will stall, resulting in missing steps and failed dispensation.

Understanding the mechanics involved in the movement of the plunger and the design of the mechanical fixings and electronic control circuitry is crucial to understanding the precision movement that results in accurate and consistent dispensation of solutions.

Overall, a thorough understanding of syringe pump operation is vital to selecting appropriate specifications and ensuring accurate experimental results.

Displacement of Fluid in the Syringe

What Moves the Syringe?

Syringe pumps use a central block that moves the plunger by converting rotational motion from a motor to linear motion using a lead screw and nut combination. Stepper motors are commonly used and controlled by driver electronics. Factors affecting syringe pump performance include the design of the central block, type of screw, connection between the screw and motor, type of stepper motor, driver electronics, and software controlling the driver. Syringe pumps are a combination of mechanical design and electronics with the stepper motor acting as the interface between the two.

Mechanics of a Syringe Pump

A syringe pump uses a lead screw mechanism to create linear motion. The lead screw is supported by a bearing at both the start and end of the moving block's travel, minimizing friction. Locking collars ensure that the screw can only rotate and not move backward or forwards. The lead screw can be connected to the motor by a coupling or drive belt, each with their own advantages and disadvantages.

A nut is used to convert the rotational motion of the lead screw into the linear motion of the moving block. The central block also has a guide in the form of a linear rail or single/dual linear rods to constrain both the carriage and the nut, preventing any rotational movement.

The distance that the central block moves for each rotation of the screw is based on the pitch of the lead screw and the number of threads. The pitch is the distance between adjacent threads. For example, a four start lead screw with a 2 mm pitch would result in 8 mm moved during each rotation of the lead screw.

Stepper Motors and Movement

A stepper motor is a type of electric motor that provides rotational movement to the lead screw, plunger, and the dispense of liquid in many machines. The motor consists of a central shaft, known as the rotor, which includes a permanent magnet and a ring of stators that are arranged around the outside of the shaft. To rotate the shaft, pairs of stators act together to attract the rotor magnet and align it with the stator. The minimum distance that the motor can rotate is referred to as a step, and in a simplified design with four pairs of stators, the minimum distance is 45 degrees.

Modern stepper motors use a hybrid design with teeth on both the rotor and stator, allowing for higher resolution of stepping. The rotor and stator teeth have equal angular spacing, and the stator pairs are offset by an angle equal to a quarter of the distance between the teeth. When the stator sets are energized, the rotor teeth align with the stator teeth, and by alternating which set is energized and which direction of current is passed through, the polarity of the stators can be in one of four different configurations.

Most stepper motors use a total of eight stators arranged in four pairs, and each stator has six teeth, resulting in an average total of 48 teeth. The rotor, however, will have 50 teeth, allowing for a stepping angle of 1.8 degrees per step. This results in a movement of 0.04 mm for an 8mm lead screw, which is larger than the minimum distance that most stepper motors can move. However, microstepping can be used to break up these steps and increase the resolution of movement.

Motor Control and Micro Stepping

A stepper motor is an electromechanical device that converts electrical pulses into rotational motion, making it ideal for precise control in many applications, including syringe pumps. The motor is controlled by a driver circuit that sends electrical pulses to the stator coils, which cause the rotor to move in a series of discrete steps. Stepper motor drivers allow for microstepping, which means that the motor can move fractions of a step by varying how energized each set of stators are. This technique can divide each individual 1.8⁰ step into as many as 256 smaller steps, resulting in an individual step angle as small as 0.007⁰.

To achieve microstepping, the driver must energize both sets of stators simultaneously and control the strength of the magnetic field generated by the stators. This is done using pulse-width modulation to reduce the average power delivered to the stators, which varies the duty cycle of the stator sets. A lower duty cycle means a lower strength magnetic field is used to move the rotor, resulting in less torque generated per microstep.

However, microstepping can lead to lower maximum force applied to the syringe, which can be problematic in some applications where high flow rates, high viscosity, or constrained flow channels are used. This is because a higher torque is required to push the syringe in these conditions, and if the torque is not high enough, the motor can stall and result in inaccurate dispense rates and volumes. Therefore, the driver must be carefully calibrated to balance the benefits of microstepping with the need for sufficient torque to achieve accurate pumping.

What are the key considerations for infusion pumps?

Portability

Infusion pumps must be portable, since patients need to be mobile both within the hospital and at home. The devices must be battery powered, relatively small, and relatively lightweight. Designers, therefore, require solutions that minimize size and power consumption. Examples include the use of switching voltage regulators instead of linear regulators, even in low-energy power supplies, and the use of higher frequency switching supplies to minimize the size of external components.

Pump Mechanism

Traditionally, stepper motors have been used in the pump mechanism to provide a precise flow rate. With angular-position sensors or Hall-effect sensors, it is possible to use DC motors instead. In these designs, the motors drive actuators (cams and fingers) to milk the tubing in precisely known fluid volumes per revolution of the mechanism.

Motor loading varies as the mechanism rotates. Motor load is affected by the position of the pump mechanism, fluid viscosity, and flow rate. To reduce power consumption, motor drive circuits can include motorload sensor signals that feed into a closed-loop control system to adjust the motor drive voltage. A variety of current-sense amplifiers, operational amplifiers, comparators, and filters are used to implement these closed-loop control systems.

Power Supplies

To maximize battery life, system designers use switch-mode voltage regulators for any significant power level. Switch-mode converters should run as fast as possible to minimize size and weight. Low-dropout linear regulators (LDOs) are used only in the very lowest power circuitry where their low efficiency can be tolerated, or where the output voltage of the LDO is not much lower than the input voltage, which keeps the efficiency high.

The use of fairly sophisticated processors places requirements on power supplies that can include voltage identification digital (VID) control from the central processing unit (CPU), fast load-step response, and precision low-voltage/high-current outputs. Digital-to-analog converters (DACs) and digital potentiometers are used in these power supplies when on-the-fly programmability is needed but VID control is not built into the regulator controller.

Because these are patient-connected devices and AC-line powered, they must meet UL® and IEC safety requirements. This means that the offline switching power supply must be designed and certified by these organizations for medical applications with patient connection.

Figure 3. Functional block diagram of an infusion pump.

Battery Management

Caregivers often need to transport patients while they remain on the IV, so the infusion pump must be able to operate from battery power alone for several hours. The use of rechargeable battery packs is mandatory.

The infusion pump absolutely must not run out of battery power; otherwise, it would stop pumping. Because of this, an accurate battery fuel gauge is required. Coulomb counting is the accepted method today, as voltage-sensing fuel gauges are not nearly accurate enough for this type of patient-connected equipment.

User Interface

The user interface is used to program the flow rate and provides a wealth of information. In addition to the infusion rate, hospital units display parameters such as the fluid being infused, patient information, the health of the pumping system, the amount of battery life remaining, and alarm conditions.

On some wearable models intended for home use, the patient is expected to do the programming. These devices benefit from intuitive graphical user interfaces (GUIs) that guide patients through the programming process. These infusion pumps frequently have color displays and touch screens for user inputs. Visible, audible, and haptic responses to user touch inputs help designers improve the user experience. Advanced touch-screen controllers like the MAX11811 offer haptic feedback, touch processing to reduce bus traffic, and autonomous modes for precision gesture detection.

Flow rates can be programmed over a very wide range: 0.01mL/hr to 999mL/hr is typical. Due to a history of medication errors caused by pump programming errors, sophisticated software routines have been implemented in infusion pumps to warn users when unusual or dangerous infusion rates are selected.

Displays/Keyboards

Full-color, high-resolution, backlit liquid-crystal displays (LCDs) are the most common. Some pumps also incorporate auxiliary alphanumeric displays. Display self-test at power-up is an FDA requirement, so designers require drivers with built-in self-test features.

Self-Test and System Monitoring

All infusion pumps must perform power-on self-test (POST) to meet FDA requirements. This includes tests of all critical processors, critical circuitry, indicators, displays, and alarm functionality. Some POST operations can require user observations, but additional circuitry is used for self-checking to reduce the risk of undetected failures.

For example, some models use a safety processor to monitor the performance of the main processor and to generate an alarm if unexpected behavior is detected. Another example of self-test is the simple monitoring of current through light-emitting diodes (LEDs) as they are turned on and off. If currents fall outside the acceptable range, a fault is indicated. Probably the most common self-test is the watchdog timer (WDT). Microprocessor supervisors with WDT functions are commonly used to ensure that the processor executes within proper code boundaries. In medical devices, it is usually not acceptable to have the supervisor on the same IC as the microprocessor, as this approach would subject the supervisor to the same transient errors as the microprocessor.

Supervisory functions are critical for ensuring that the pump is operating properly during patient use. Microcontrollers (of which there are often several in a single pump) must be held in reset until all power supplies are within tolerance and stable. All power supplies are monitored with voltage supervisors for undervoltage and overvoltage conditions. Motor loading is monitored and motor-stall detection is provided. (Motor stall is a critical failure causing a top-priority alarm.) Because of the criticality of the system, often power-supply voltages are monitored with ADCs so that their exact value can be recorded periodically. ADCs are also needed for sensor readings, such as temperature, motor loading, IV line pressure, and battery voltage.

Temperature sensing is implemented in the battery pack, the power supply, the motor, and the display. Due to the high efficiency of these designs, fans are usually not needed. These pumps must be splash-proof, so it is difficult to put in openings for airflow.

Alarms

Infusion pumps require audible and visible alarms to alert users to faults or potentially dangerous conditions. Bicolor or tricolor (red/orange/green) LEDs are typically used as visual indicators. Audible alarms vary from simple beepers driven by the microcontroller's pulse-width modulation (PWM) output to more sophisticated alarms (such as voice synthesis) created with an audio DAC.

Even simple audio beepers should include a self-test feature. This function can be implemented either indirectly by monitoring for a speaker impedance within range or directly by incorporating a mic near the speaker to register the audio output and confirm that it is at the proper level.

Timekeeping

Due to the criticality of patient care, every event needs to be logged and time stamped. Every key press, every start and end of an infusion, every change of configuration (pump door opening/closing, AC power disconnect, etc.), and every reported fault condition needs to be logged and time stamped for later review in case of lawsuits or instrument malfunction.

A real-time clock (RTC) is required. Since other clock sources for microprocessors and digital circuitry are not especially critical, standard crystals can be used. If extreme accuracy is needed for the RTC, Maxim has RTCs with built-in temperature-compensated crystal oscillators (TCXOs) that achieve an accuracy of ±2ppm (0°C to +40°C), which is about two orders of magnitude more accurate than a standard crystal.

Electrostatic Discharge

All infusion pumps must pass IEC 61000-4-2 electrostatic discharge (ESD) requirements by either using electronics with built-in protection or by adding ESD line protectors to exposed traces. Maxim offers many interface parts with this high ESD protection built-in, as well as stand-alone ESD diode arrays.

Interfaces

Modern infusion pumps include interfaces to connect to hospital information systems. These are variously hardwired (RS-232, RS-485, USB, and Ethernet) and/or wireless interfaces (Bluetooth® and Wi-Fi®).

For wired interfaces, galvanic isolation is critical to meet the patient safety requirements of IEC 60601-1. Interfaces with unidirectional lines (such as RS-232, RS-485, RS-422) are not difficult to isolate. The only challenge is to create an isolated supply for them residing on the isolated side. An integrated device such as the MAX256 can solve this challenge by providing up to 3W of isolated power for isolated interfaces from a compact SO package.

No comments:

Post a Comment